What does SMD Elements® Design software do that this app doesn’t?

Our in-house developed Microsoft Windows based design software created by our principals, Structural Metal Decks Ltd, UK, enables you to carry out complex floor slab or roof design calculations using SMD products. The Intuitive tabbed interface, 3D design graphics and message pane helps ensure compliant calculations are created with practical implications in mind.

Floor Deck Calcs

Where SMD Elements® Mobile provides the user with simple maximum span limits, the full, Windows based software, allows the user to run calculations in far more detail, inputting loadings and slab conditions with the option to create a full design report for a given specification.

For guidance to use the software, Jamie Turner, SMD Technical Development Director, has created a tutorial with step-by-step guidance for slab calculations.

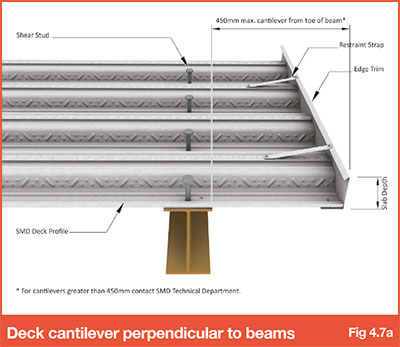

What is the maximum deck cantilever achievable?

Cantilevers or slab edge overhangs are constructed using deck, edge trim or a combination of both. In cantilever locations, the deck and/or edge trim acts as permanent formwork only and does not contribute to the tensile reinforcement for the cantilever. The slab cantilever in the final condition must be designed as fully reinforced considering the mesh reinforcement in the surface of the slab and taking no contribution from the deck and/or trim, to determine whether any additional reinforcement is required to support the final imposed loads. The design and detailing of this reinforcement are the responsibility of others.

Where deck spans perpendicular to the edge beam in the direction of the cantilever (refer to Fig 4.7a), a maximum dimension of 450mm is recommended. This is a practical limitation for health and safety reasons, as typically the handrail is located on beam centre line and extending the cantilever further may result in unsafe practice beyond the handrail when stitching trim to the end of the sheet.

Is it OK to cut holes in a composite deck slab?

When it is necessary to form service holes in a composite slab the following general rules are recommended. For openings at right angles to the deck span:

Small (<250mm): these require no special treatment (i.e. no additional reinforcement). Prior to placing of concrete the opening is boxed out.

Medium (250mm – 700mm): Additional reinforcement is required around the opening, generally designed in accordance with BS EN 1992-1-1 or BS8110.

Large (>700mm): Structural trimming steelwork designed by others and supplied by the steelwork fabricator, is recommended.

All holes should be cut using non-percussive methods to ensure the bond between deck and concrete is not damaged.

Should a composite deck slab be poured to a fixed datum?

No is the typical answer to this, slabs should be poured to constant thickness unless the frame has been specifically designed with a pour to datum un mind – refer extract from Concrete Society Technical Report No 75 which states: “Most composite floor slabs are constructed to a constant thickness and therefore will follow the steel decking and steel beam profiles, which will tend to give poor control over the level to datum. For this reason, it is not normally checked or specified.

If the specifier insists on a control of the surface to a datum, then the steel beam and steel decking should be designed with minimum deflection. The compound deflection of the steel decking, secondary and primary beams should be considered and taken into account.

Where a strict control to datum is required, it is suggested that the deflection of the steel beams is limited to 10mm.”

Which fixings do I need to use when installing the deck?

Where steel beams are to receive thru-deck welded shear studs, Hilti X-P14 G3 MX, Hilti X-U 15 (DAK) or similar approved.

Where no shear studs are specified, Hilti X-ENP 19 or Spit SBR 14 shot-fired nails or similar approved should be used.

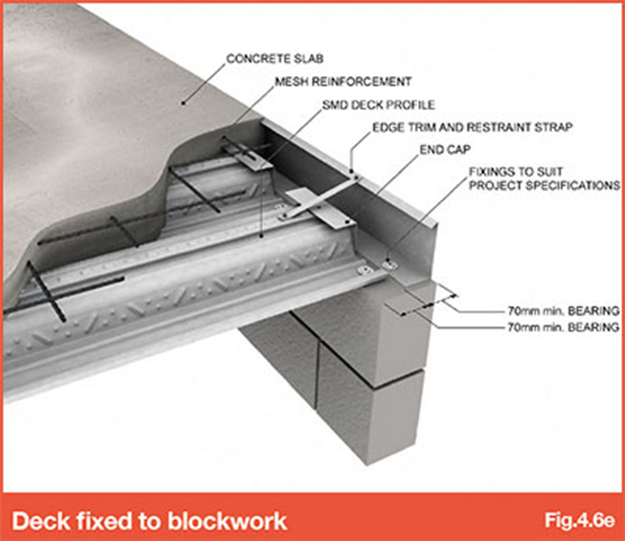

Fixings to masonry should be either Drill & Hammer Anchors (Spit P370 or P560, or similar approved) or shot-fired fixings (Hilti X-SW or Spit CR9 shot-fired nails or similar approved)

Fixings to Timber/Glulam Beams, or where shot-fired fixings are not permitted, should be self-drilling screws Fixfast DF12 5.5mm, Hilti S-MD55Z 5.5mm, or similar approved.

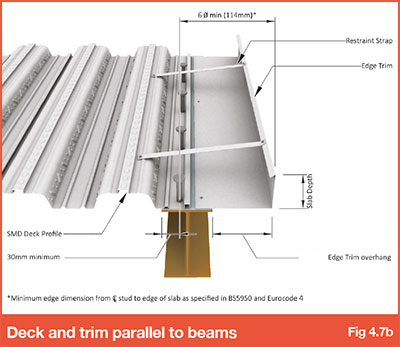

At side-stitching of sheets and/or restraint strapping of edge trim, Hilti S-MD01Z 4.8 x 19, Fixfast DF3 HEX 4.8 x 20, or similar approved.

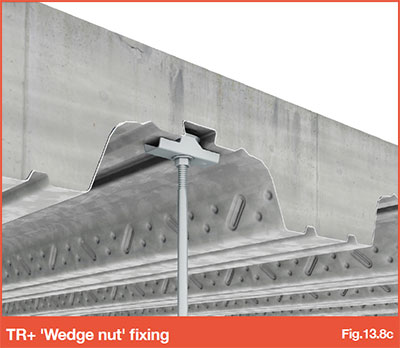

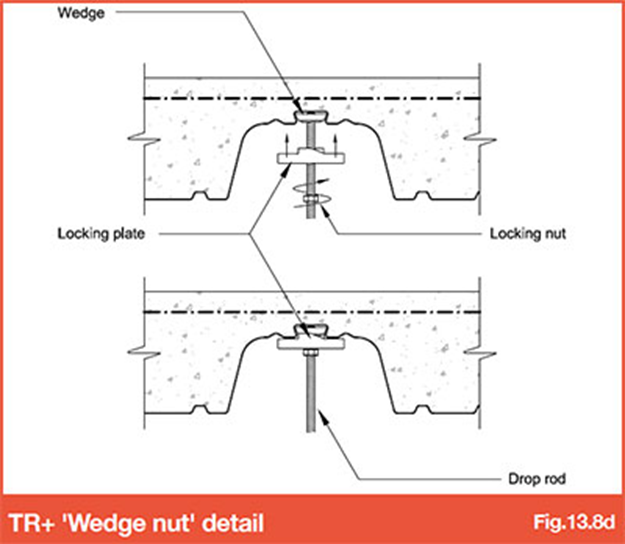

Is it possible to use soffit hangers for M&E?

Yes, there are 2 approved products which allow soffit hangers to be installed with any of SMD’s composite floor deck profiles;

These can be purchased directly from Lindapter International (www.lindapter.com) or through their network of distributors.

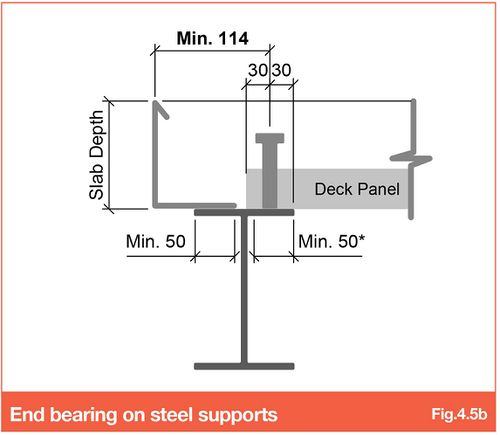

What is the minimum bearing for the deck?

The minimum bearing requirements for the decking are 50mm on steelwork (this is increased to 60mm where sheets are to receive thru-deck welded shear studs) and 70mm on masonry or concrete.

To reduce the structural zone, it is sometimes necessary to install the decking onto angles fixed to the beam webs or bottom flanges. Where deck ends are supported on shelf angles or bottom flanges between beam webs, the shelf angle or bottom flanges must be designed to extend a minimum of 50mm beyond the toe of the beam top flange. This minimum dimension of 50mm is essential to enable the sheets to be physically positioned between toes of top flanges and provide access for a cartridge tool to be used to secure the decking into place

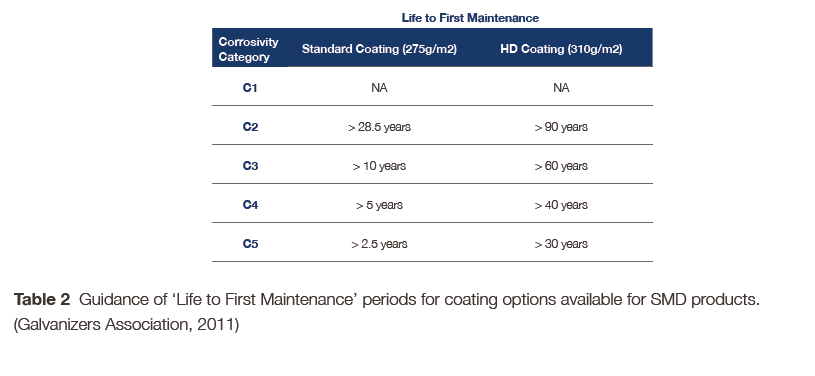

Can decking be used in external environments?

Decking can be used for internal, external and corrosive environments. However, there are several important considerations and options before deciding which deck to specify;

SMD offer a High Durability (HD) which has a mass coating of 310g/m2 (approximately 25m per face) which has a greatly improved Life to First Maintenance and can be used in external or corrosive environments.

Do we need to use shear studs?

Thru-deck welded shear studs are commonly used to transfer horizontal shear forces between the steel beam and concrete slab to suit the relevant design standard. These are called Composite Beams. Where beams are Non-Composite, there may not be a need for studs and shot-fired fixings can be used (typically Hilti ENP-19 or similar approved).

Not every beam might require studs so if in doubt, speak to the Project Engineer to confirm if studs are required.

Should a composite deck slab be poured to a fixed datum?

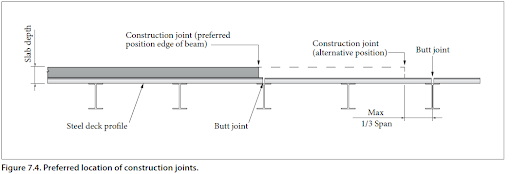

For construction joints running parallel to the deck ribs, the location of the joint is less critical. It is recommended that this be placed in close proximity to a beam position (i.e. in the region of 750mm), but away from the shear stud locations.

If a pour stop needs to be formed in an emergency, the joint should be located no greater than 1/3 of the over span into the bay.